Subsea detailed structural engineering is a critical discipline in the offshore industry focused on designing and analyzing structures and equipment for underwater environments. It involves applying advanced engineering principles to ensure the integrity and safety of subsea structures, such as pipelines, risers, platforms, and equipment.

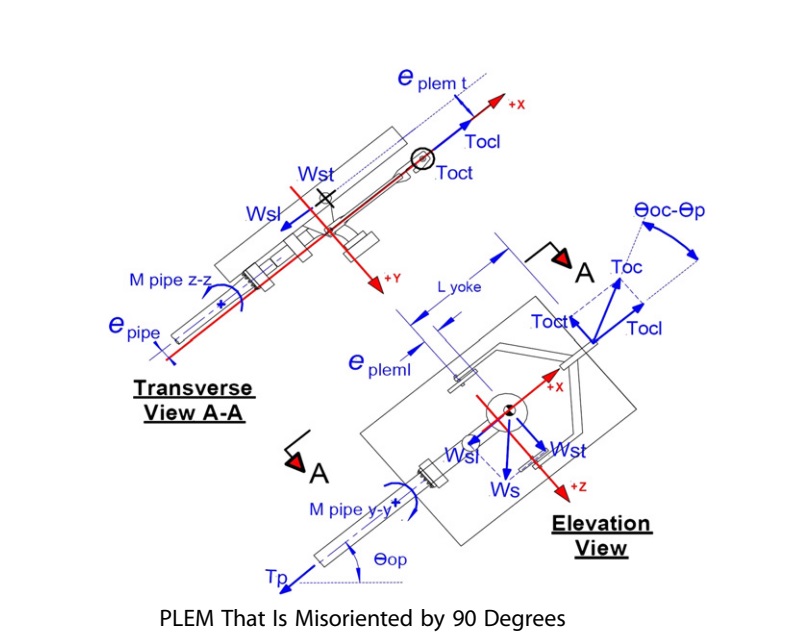

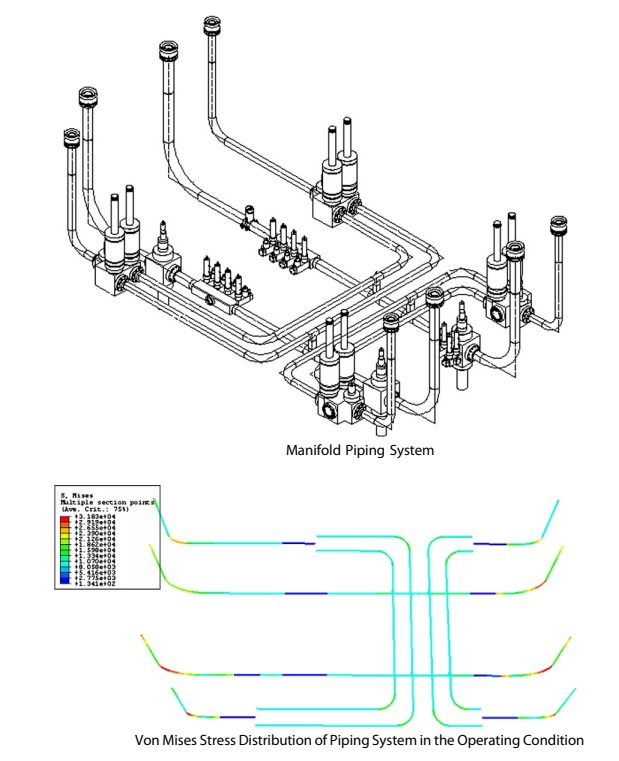

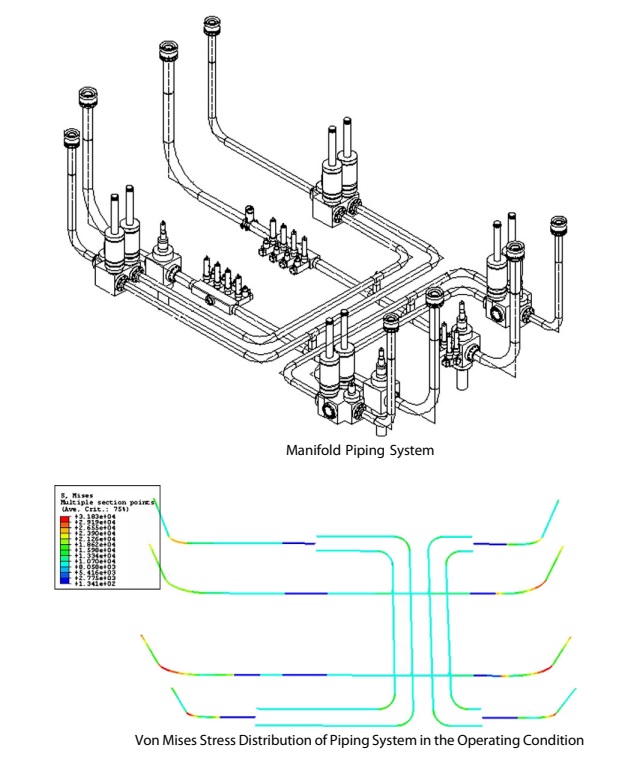

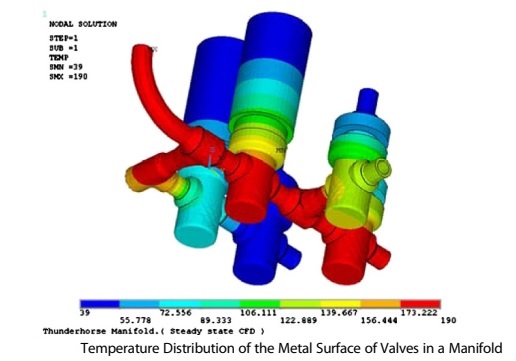

Our engineers design subsea structures to withstand extreme environmental conditions, including high pressures, corrosive seawater, and dynamic loads from waves, currents, and vessel motions. Using advanced analysis techniques, such as finite element analysis (FEA), we accurately predict structural behavior and assess integrity.

Beyond the design phase, WIW Engineering plays a crucial role during the fabrication and installation of subsea infrastructure. Our team ensures structures are manufactured and installed in accordance with industry standards and best practices. We collaborate closely with geotechnical and pipeline engineering disciplines to maintain system integrity throughout the project lifecycle.

Continuous monitoring is essential to ensure the long-term performance of subsea assets. WIW engineers develop inspection and maintenance programs to detect and address potential damage from fatigue, corrosion, or marine growth, working closely with asset integrity teams to mitigate risks.

Our subsea structural engineering expertise combines technical excellence, innovation, and deep knowledge of the harsh subsea environment. Our team has vast experience in the detailed design of subsea components, including:

WIW Engineering provides a full suite of specialized structural analyses:

WIW's commitment to excellence ensures that every subsea system we engineer is robust, reliable, and optimized for long-term offshore operation.